I intend for this post to assist you in finding suitable manufacturers as you embark on your business journey. It helps you communicate well with factories and find the best one for your needs.

Things you should do before contacting manufacturers

Before you start looking for factories, there are some things you need to prepare in advance.

Clarify the clothes you need

First, decide what kind of clothes you need, and their important qualities, and find similar products to compare. Typically, clothing factories specialize in specific types of garments.

For instance, my manufacturer specializes in producing garments made from polyester and nylon, such as swim shorts and leggings. However, we are unable to manufacture items like down jackets or denim jeans as they require completely different machinery.

Prepare the pattern and logo

If you need to print patterns and your logo on your clothing, it’s advisable to prepare high-resolution files in advance and save them in formats like .pdf, .ai, .png, or .cdr, which are convenient for designers.

It’s preferable not to provide designers with physical images, as this means they would have to redraw the patterns based on the image. This typically incurs additional costs and requires more time.

Identify your benchmark products

Before ordering customized products, you expect them to be of the same quality as a popular brand. When contacting the factory, you can directly communicate this expectation, which is highly beneficial. It helps the factory quickly understand the quality details and fabric standards you are looking for in your products.

Ready goods or custom products?

Do you need ready-made goods or custom products? This question is crucial.

Typically, ready-made goods have lower quantity requirements, and the prices are very affordable. If you want custom items, you will need to spend time explaining your requirements to the factory. Additionally, you should prepare for a longer wait. Customized products also tend to be a bit more expensive.

How to negotiate with manufacturers

When communicating with the factory, it’s essential to clarify the following details:

Minimum Order Quantity(MOQ)

Before you start, please ask about the factory’s Minimum Order Quantity (MOQ). For most clothing factories, 100 pieces per design is a common MOQ. If your plan doesn’t meet this requirement, ask if the factory will accept smaller amounts for a slightly higher cost.

Quality

The primary factors influencing clothing quality are the fabric and the garment’s pattern. Before placing an order, it’s crucial to inform the factory about your benchmark products. If the factory says they can make the same quality, ask for a sample to check if it’s what you want. If this is acceptable, then you can proceed with the formal order.

Price

At this stage, there are primarily two costs involved: the factory’s ex-factory price and the shipping cost to your warehouse.

Ex-factory price

The factory will calculate a final ex-factory price based on the samples they produce for you. You can negotiate with the factory in a friendly manner, asking for around a 10% discount, for example. Usually, factories set aside some profit for bargaining, so discounts within this range are often agreed upon easily. But don’t ask for too much of a discount, like 50%, because the factory might see that as disruptive.

Shipping cost

Next, the factory typically helps calculate the shipping cost for you. The shipping cost is calculated by the freight forwarding company and then given as a quote to the factory. The factory adds a portion of the profit before quoting it to you.

To get the best shipping price, ask for an estimate of the weight and volume of your goods. Volume is important too, so know the volume of your goods, also called CBM.

You can search for freight forwarding companies online. Give them the weight, volume, and destination of your goods. They will then calculate the shipping cost for you. At this stage, you can reach out to 10 or even 20 freight forwarding companies for quotes. After receiving the quotes, eliminate the lowest and highest ones (unrealistically low freight costs are often subject to additional charges later), and choose the one that you find most reliable for your shipping needs.

The shipping cost provided by freight forwarding companies is typically inclusive of taxes. They may use various strategies, such as undervaluing goods, to minimize tax liabilities. While this is not illegal, it often results in a slightly lower cost compared to paying taxes directly, making it a common practice.

Additionally, sea freight is a more cost-effective option, especially if you have ample time.

Calculate profit

Next, by adding the ex-factory price, shipping cost, and tax, you arrive at your purchasing cost. Typically, your selling price should be at least two to three times higher than the purchasing cost to be reasonable. This means that as long as you can sell half of your stock, you’ll break even. If you plan to sell through e-commerce channels, don’t forget to factor in platform advertising fees and transaction fees.

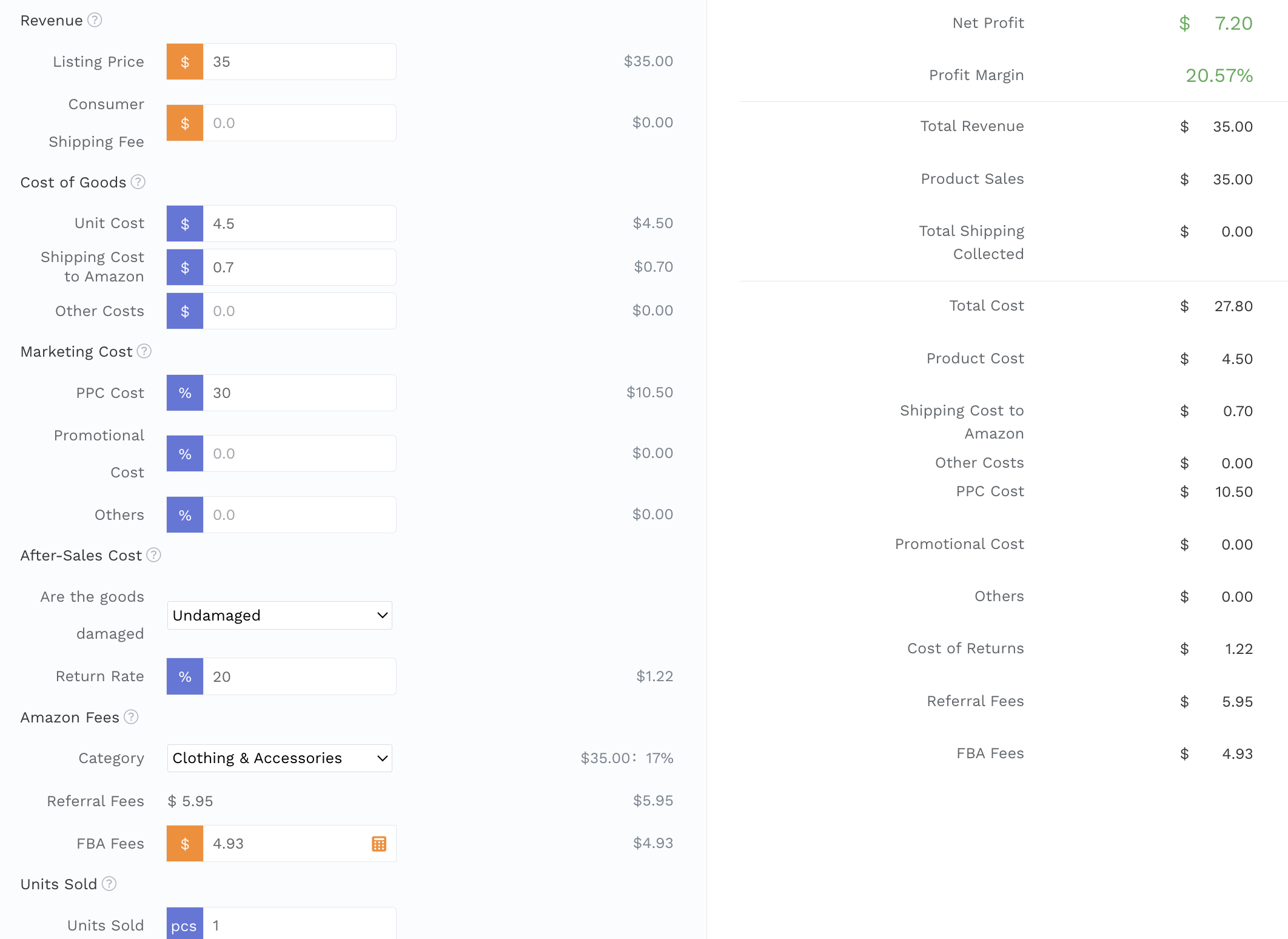

For example, my client orders swim trunks from me and sells them on Amazon. I provide them with an ex-factory price of $4.5 per unit, and the shipping cost translates to approximately $0.7 per unit to his warehouse. Amazon charges a 17% transaction fee for the clothing category, and the final delivery cost is around $5 per unit. They allocate 30% of the product’s selling price to Amazon’s in-site advertising. Considering a return rate of approximately 20% for clothing, they set the front-end selling price at $35. This results in a net profit margin of around 20.5%.

When you sell online, the fees for advertising, commissions, and shipping at the end make up most of your profits. Compared to these factors, the price of the product itself has less impact than one might initially think.

Lead time

After confirming the order, it’s crucial to finalize the delivery time with the factory. It’s important to note that delayed deliveries are quite common, especially when your order is relatively small.

The factory might prioritize larger clients, leading to a lower priority for your order. This is why it’s essential to allocate sufficient time. If your products have strong seasonality, such as the swim trunks produced in our factory, timing becomes particularly critical.

Where to find

You can find such manufacturers through Google, social media platforms like Facebook, and certain B2B websites such as Alibaba, Made in China, etc.